Sisebenzisa ifomula ye-no-dysprosium kwiimveliso ezijikelezayo ezisezantsi kubathengi ukunciphisa iindleko.Sinefomula ezinzileyo enokwenziwa kwiimveliso ezilinganayo zobushushu obuphantsi.Inciphisa iindleko kunye nokwandisa ukusebenza kakuhle ngakumbi kubathengi ngokulawula ngokungqongqo ukunyamezelana ekuqhubeni kunye nokwaleka ngokweemfuno ezahlukeneyo zabathengi ukuqinisekisa ukuzinza kokhuseleko lwe-plating ngaxeshanye, kubandakanywa isitshizi setyuwa, amandla okubopha, ukuxhamla kwe-colloid njalo njalo. .

Iimveliso ezijikelezayo zixhomekeke kwiikona ezilahlekileyo kwinkqubo yokuvelisa.Ke sinezixhobo zokuhlola ezizenzekelayo ezipheleleyo zokunyamezela inkangeleko, ezinokuqinisekisa iziphene zemveliso ngaphakathi koluhlu olulawulekayo kwaye uphephe iimveliso ezineziphene ekusebenziseni inkqubo.

Ngokuhambelana nokuguquguquka okuguquguqukayo, siqinisekisa ukuba iziko lomlilo eligxininisiweyo lihambelana nolawulo lwenkqubo yemagnethi, kunye nesixhobo sokuhlola esigcweleyo semagnethi ukuthintela iimveliso ezibuthathaka zemagneti ukuba zigeleze ziye kubathengi.Ngokuphathelele ukupakishwa kwemagneti, inkampani yethu ilandelele izixhobo ezizenzekelayo zokufaka ikhowudi yemagnethi ukuthintela abasebenzi ukuba bangahlawulisi intlawulo kazibuthe.

Ngokubhekiselele kulawulo lokuhanjiswa, inani elikhulu loomatshini bokusika bemigca emininzi, iiyunithi zokusika, abasebenzi abaqolileyo bokusebenza kwezobugcisa, ukubeka iliso kwenkqubo yemveliso egqibeleleyo, inyathelo ngalinye lokwenziwa kwemveliso kunye nokuveliswa kunokufumana ingxelo yenkqubela phambili nangaliphi na ixesha, umgca wokuvelisa imveliso yecylindrical evuthiweyo, ukuqinisekisa iimfuno zolawulo lwabathengi ekuhanjisweni kwemveliso, kunye nenkqubela phambili yokuvelisa elawulwayo.

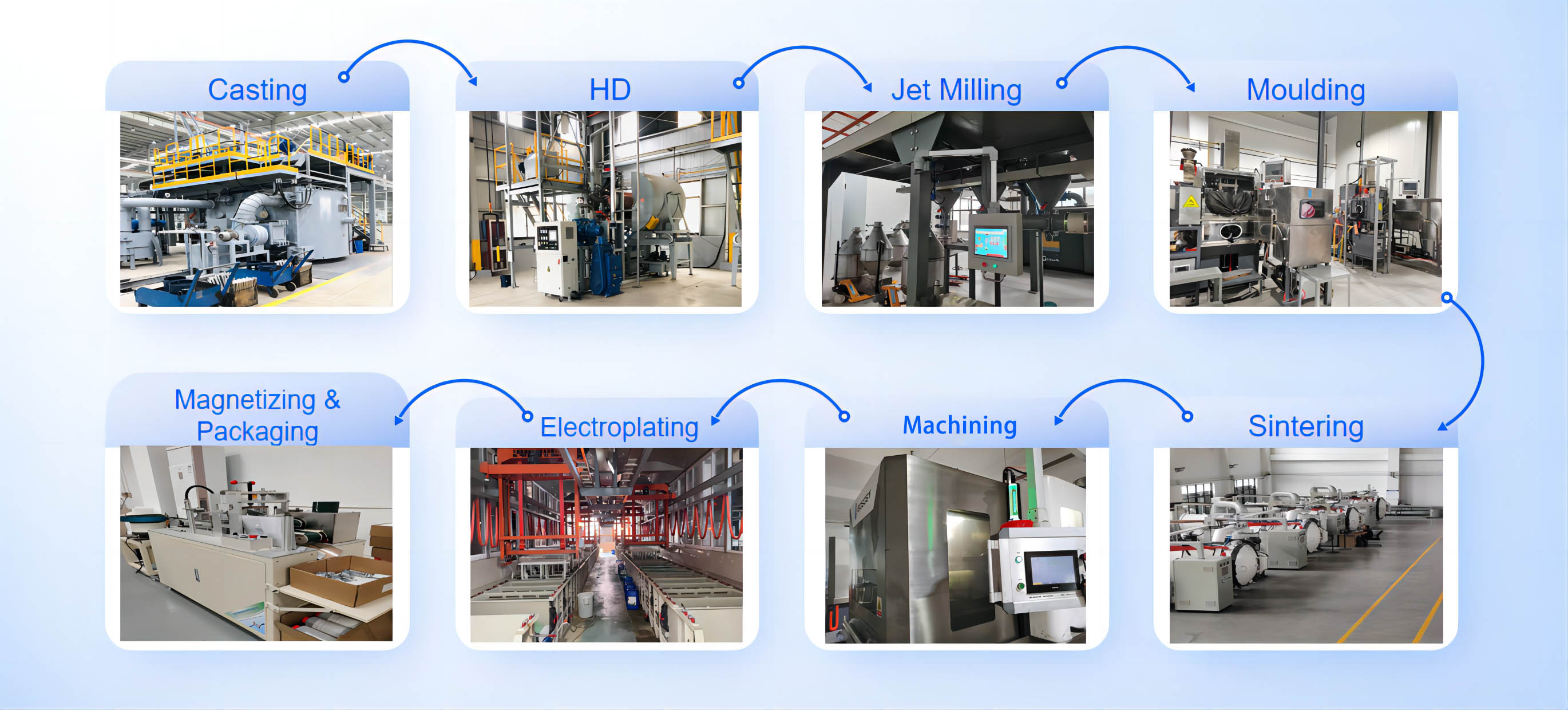

Inkqubo yeMveliso yeNdFeB

Ukwaleka Intshayelelo

| Umphezulu | Ukwaleka | Ukutyeba μm | Umbala | Iiyure ze-SST | Iiyure zePCT | |

| Nickel | Ni | 10~20 | Isilivere eqaqambileyo | >24 ukuya kutsho ku72 | >24 ukuya kutsho ku72 | |

| Ni+Cu+Ni | ||||||

| I-Nickel emnyama | Ni+Cu+Ni | 10~20 | Umnyama Oqaqambileyo | > 48-96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5 ~8 | UBrighe Blue Umbala Oqaqambileyo | >16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Isilivere | > 36 -72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Igolide | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Isilivere | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Mnyama / Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15 ~ 30 | >72 ~108 | --- | |||

| Zn+Epoxy | 15 ~ 25 | >72 ~108 | --- | |||

| Ukunyamezela | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana | --- | |

| Iphosphate | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana) | --- | |

Iimpawu zoMzimba

| Into | Iiparamitha | Ixabiso leReferensi | Iyunithi |

| I-Magnetic encedisayo Iipropati | I-Coefficient yoBubushushu obubuyiselwayo ye-Br | -0.08--0.12 | %/℃ |

| I-Coefficient yoBubushushu obubuyiselwayo ye-Hcj | -0.42-0.70 | %/℃ | |

| Ubushushu obuthile | 0.502 | KJ ·(Kg ·℃)-1 | |

| Ubushushu beCurie | 310~380 | ℃ | |

| Mechanical Physical Iipropati | Ukuxinana | 7.5~7.80 | g/cm3 |

| Vickers Ukuqina | 650 | Hv | |

| Ukunyangwa koMbane | 1.4x10-6 | μQ · m | |

| Amandla acinezelayo | 1050 | MPa | |

| Tensile strength | 80 | Mpa | |

| Ukugoba Amandla | 290 | Mpa | |

| I-Thermal Conductivity | 6 ukuya ku-8.95 | W/m ·K | |

| Imodulus yolutsha | 160 | GPA | |

| Ukwandiswa kweThermal(C⊥) | -1.5 | 10-6/℃-1 | |

| Ukwandiswa kweThermal(CII) | 6.5 | 10-6/℃-1 |

Umboniso Wemifanekiso