Bakeng sa boholo, k'hamphani ea rona e na le mochini o hlophisang boholo ba arc oa Keyence, o fokotsang kotsi e bakiloeng ke sehlopha se sebe sa kopano ea taolo ea mamello, karolo ea kopano ea magnet ea bareki.

Ho sa tsotellehe hore na ke mofuta ofe oa ho roala, kaofela ha rona re ka etsa bonnete ba hore phekolo e khethehileng ea arc holim'a karolo ea colloid affinity ea makenete ho litharollo ts'ebetsong ea ts'ebeliso moo thupa, tsitsipano e kentsoeng ea sekhomaretsi e sa lekaneng joalo-joalo.

Bakeng sa ho fana ka mantsoe, re na le likheo tse fapaneng ka boholo le limaraka tse fapaneng, bakeng sa ho etsa prototype makenete ka nako efe kapa efe.Re odara phofo ka bongata esale pele e le hore theknoloji ea alloy dual alloy e ka khotsofatsa litlhoko tsa phepelo ea bareki kamora ho fumana tlhoko ea bareki.

Khamphani ea rona e na le sehlopha sa litsebi tsa mahlale le tsa thekiso tse ka fanang ka likeletso tsa tekheniki, sekema sa kopano ea magnet, le palo e kholo ea linyeoe tsa ts'ebeliso ka nako efe kapa efe ho netefatsa hore ha ho na matšoenyeho a mang mabapi le ts'ebeliso ea bareki.

Re latela ka tieo litekanyetso tsa taolo ea ts'ebetso, taolo ea phallo ho latela sistimi ea IATF16949, ho netefatsa phano le tlhahlobo ea boleng bakeng sa bareki.

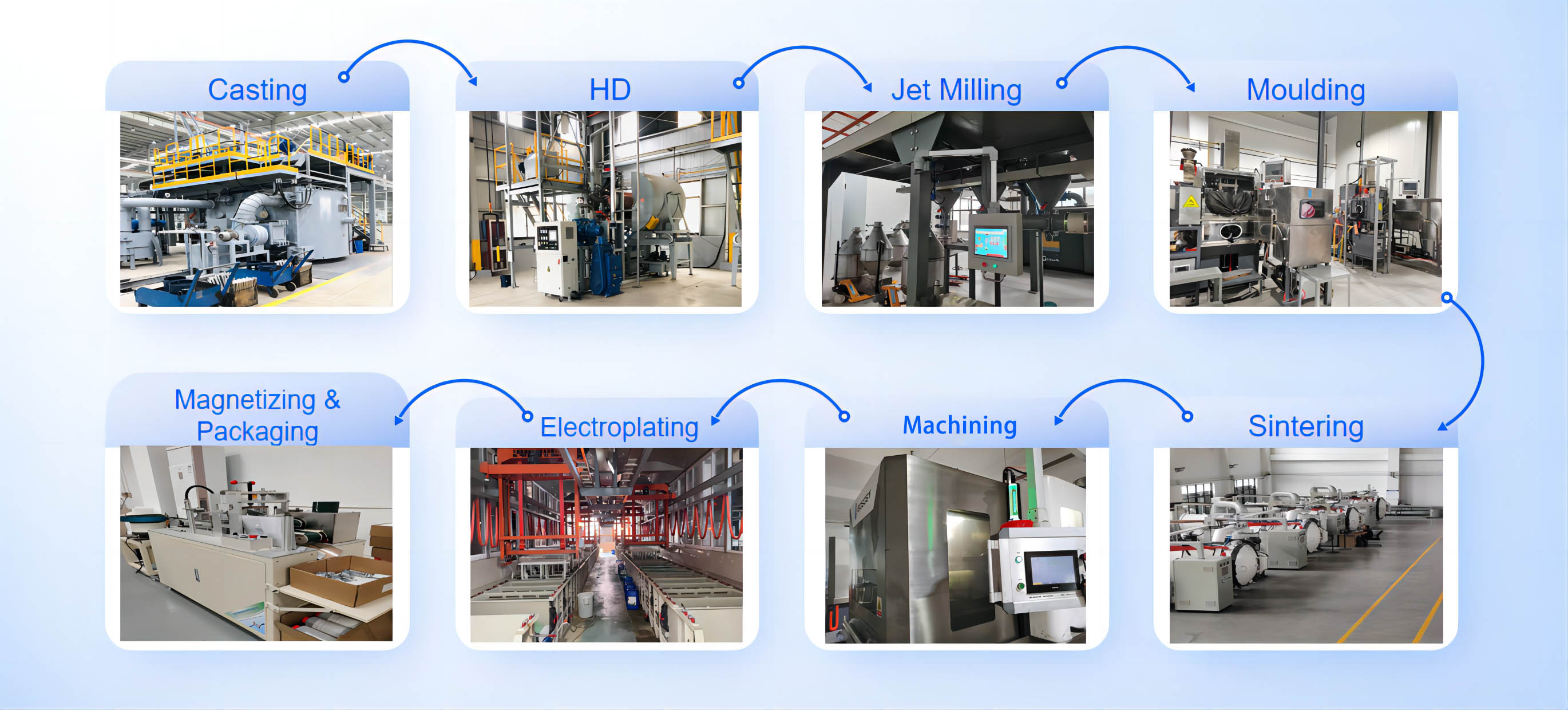

Mokhoa oa Tlhahiso ea NdFeB

Selelekela sa Coating

| Bokaholimo | Ho roala | Botenya μm | Mmala | Lihora tsa SST | Lihora tsa PCT | |

| Nickel | Ni | 10 - 20 | Silevera e Khanyang | > 24 -72 | > 24 -72 | |

| Ni+Cu+Ni | ||||||

| Nickel e Ntšo | Ni+Cu+Ni | 10 - 20 | Botsho bo kganyang | > 48-96 | > 48 | |

| Cr3+Zinc | Zn C-Zn | 5 - 8 | Brighe Blue Mmala o benyang | > 16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 - 25 | Silevera | > 36 -72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Khauta | >12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Silevera | >12 | > 48 | |

| Epoxy | Epoxy | 10 - 20 | Botsho/ Bohlooho | > 48 | --- | |

| Ke+Cu+Epoxy | 15-30 | > 72 ~108 | --- | |||

| Zn+Epoxy | 15-25 | > 72 ~108 | --- | |||

| Boikemisetso | --- | 1 - 3 | Boputsoa bo Lefifi | Tshireletso ya Nakwana | --- | |

| Phosphate | --- | 1 - 3 | Boputsoa bo Lefifi | Tšireletso ea nakoana) | --- | |

Litšobotsi Tsa 'Mele

| Ntho | Mekhahlelo | Boleng ba Reference | Yuniti |

| Magnetic e thusang Thepa | Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42–0,70 | %/℃ | |

| Mocheso o khethehileng | 0.502 | KJ·(Kg ·℃)-1 | |

| Mocheso oa Curie | 310~380 | ℃ | |

| Mechini ea 'Mele Thepa | Botenya | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Ho hanyetsa Motlakase | 1.4x10-6 | μQ ·m | |

| Matla a Khatellang | 1050 | MPa | |

| Matla a tšepe | 80 | Mpa | |

| Matla a Kobehang | 290 | Mpa | |

| Thermal Conductivity | 6 ho isa ho 8.95 | W/m ·K | |

| Modulus ea Bacha | 160 | GPA | |

| Katoloso ea Mocheso(C⊥) | -1.5 | 10-6/℃-1 | |

| Katoloso ea Thermal(CII) | 6.5 | 10-6/℃-1 |

Pontšo ea Litšoantšo