Waxaan u isticmaalnaa caanaha aan dysprosium-ka lahayn alaabta wareega-hoose ee macaamiisha si loo yareeyo kharashyada.Waxaan haynaa qaacido xasiloon oo laga samayn karo wax soo saarka heerkulka hooseeya.Waxay yaraynaysaa kharashyada waxayna kordhisaa waxtarka dheeraadka ah ee macaamiisha si adag u xakameynaya dulqaadka habka iyo dahaarka iyadoo loo eegayo shuruudaha kala duwan ee macaamiisha si loo hubiyo xasiloonida ilaalinta dajinta waqti isku mid ah, oo ay ku jiraan buufin milix ah, xoogga dahaarka, xiriirka kolloid iyo wixii la mid ah. .

Alaabooyinka wareega waxay u nugul yihiin geesaha maqan ee habka wax soo saarka.Markaa waxaanu si toos ah u haysanaa qalab baadhitaan buuxa oo loogu talagalay dulqaadka muuqaalka, kaas oo hubin kara cilladaha badeecada gudaha xadka la xakamayn karo kana fogaanayo alaabada cilladaysan ee isticmaalka habka.

Marka la eego joogteynta qulqulka, waxaan hubineynaa foornada sintering-ka go'an si joogta ah ee kantaroolka habka magnetka, iyo qulqulka magnetic qalabka kormeerka buuxa si looga hortago alaabooyinka magnetic daciifka ah inay u qulqulaan macaamiisha.Marka la eego baakadaha magnetization-ka, shirkadeena waxay la socotaa qalabka magnetization codeing si toos ah si looga hortago in shaqaaluhu ku xad-gudbaan kharashka magnetka.

Marka la eego xakamaynta gaarsiinta, tiro badan oo mashiinada goynta multi-line, gooyn unugyada, shaqaalaha processing farsamo bislaaday, habka wax soo saarka kaamil ah la socodka, tallaabo kasta oo ka mid ah wax soo saarka iyo wax soo saarka ka heli kartaa jawaab celin horumarka mar kasta, line wax soo saarka cylindrical qaan, si loo xaqiijiyo shuruudaha xakamaynta macaamiisha ee keenista alaabta, iyo sidoo kale horumarka wax soo saarka la xakamayn karo.

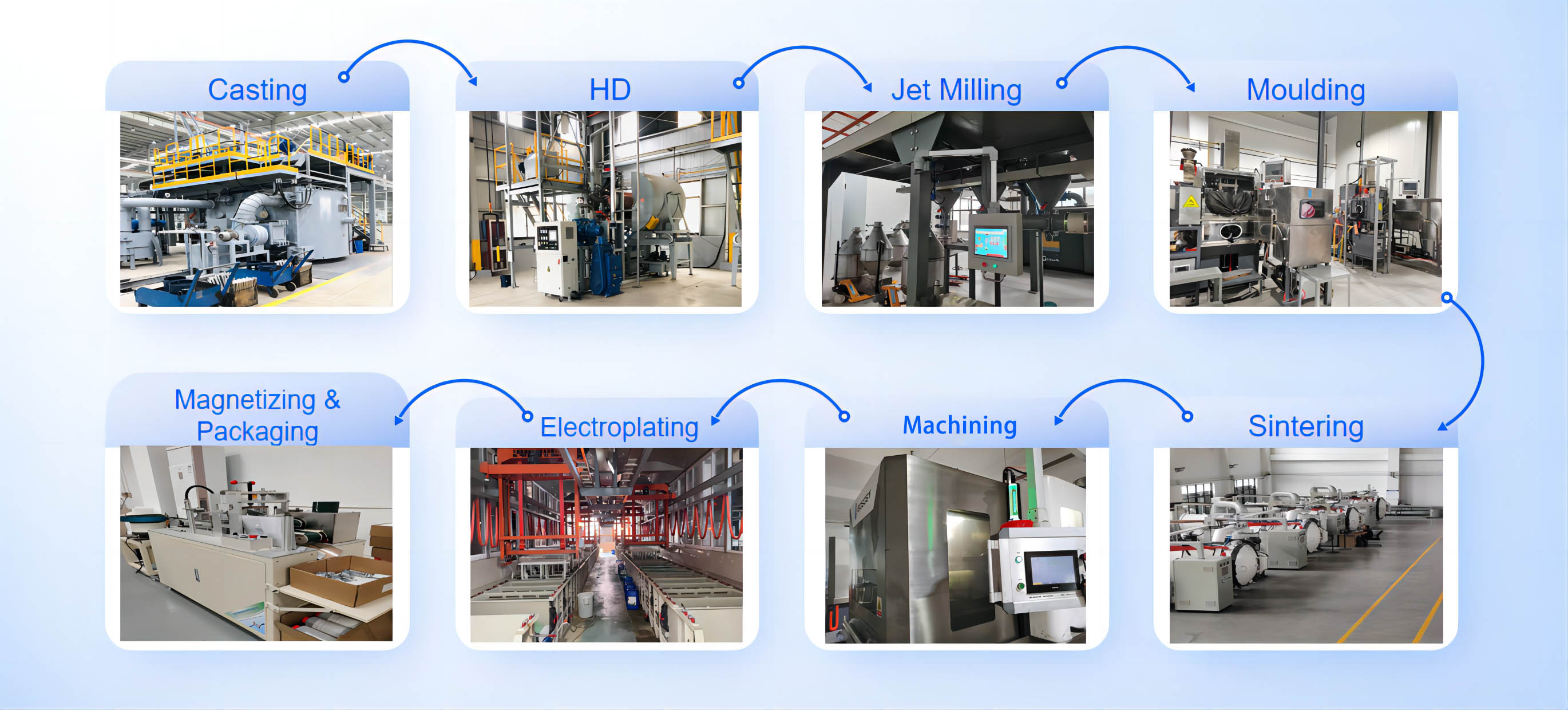

Habka Waxsoosaarka NdFeB

Hordhac Dahaarka

| Dusha sare | Dahaarka | Dhumucda μm | Midabka | Saacadaha SST | Saacadaha PCT | |

| Nikkel | Ni | 10 ilaa 20 | Silver dhalaalaya | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nickel madow | Ni+Cu+Ni | 10 ilaa 20 | Madow dhalaalaya | >48~96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5~8 | Brighe Blue Midabka dhalaalaya | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ilaa 25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 ilaa 15 | Dahab | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ilaa 15 | Silver | >12 | >48 | |

| Epoxy | Epoxy | 10 ilaa 20 | Madow/Cawlan | >48 | --- | |

| Ni+Cu+Epoxy | 15 ilaa 30 | >72~108 | --- | |||

| Zn+Epoxy | 15 ilaa 25 | >72~108 | --- | |||

| Dareenka | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah | --- | |

| Fosfate | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah) | --- | |

Astaamaha Jirka

| Shayga | Halbeegyada | Tixraaca Qiimaha | Unug |

| Kaaliyaha Magnetik Guryaha | Isku-dhafka Heerkulka La-noqon karo ee Br | -0.08--0.12 | %/℃ |

| Isku-dhafka Heerkulka La-noqon karo ee Hcj | -0.42~-0.70 | %/℃ | |

| Kuleylka Gaarka ah | 0.502 | KJ · (Kg ·℃)-1 | |

| Heerkulka Curie | 310 ~ 380 | ℃ | |

| Mechanical Physical Guryaha | Cufnaanta | 7.5-7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Iska caabinta Korontada | 1.4x10-6 | μQ ·m | |

| Xoog isku dhejisan | 1050 | MPa | |

| Xoogga Jilicsan | 80 | Mpa | |

| Xoog Laabashada | 290 | Mpa | |

| Habdhaqanka kulaylka | 6 ilaa 8.95 | W/m ·K | |

| Modulka dhalinyarada | 160 | GPA | |

| Balaadhinta kulaylka (C⊥) | -1.5 | 10-6/℃-1 | |

| Balaadhinta kulaylka (CII) | 6.5 | 10-6/℃-1 |

Muujinta Sawirka