Codsiga: giraanta NdFeB waxaa si weyn loogu isticmaalaa matoorka koobka bannaan, mashiinka nadiifiyaha vacuum, mashiinka timaha qalajiyaha, cod-baahiyaha iyo meelo kale.Codsiyada mootada, waxay leedahay shuruudo aad u sarreeya oo ku saabsan cabbirka joomatari ee magnetka iyo hantida magnetka, dulqaadka ugu yar wuxuu noqon karaa 0-0.03mm. Codsiyada cod-baahiyaha, magnetka ayaa sida caadiga ah leh daahan Zn, gaarsiinta xaalad aan-magnetized ahayn, darajada magnet sida N, M iyo H taxanaha darajada, sida caadiga ah sameecado magnet uma baahna darajo sare. Codsiga kale waa suuqa isqurxin, waxaan siinaynaa malaayiin xabbadood giraanta magnetka our macaamiisheena adduunka oo dhan, magnets waxaa loo isticmaalaa sanduuqa baakadaha, axial magnetized ama axial multipole magnetized sida 2 ama 4 tiirarka, oo ma aha oo kaliya magnet saafi ah, waxaan sidoo kale avaialbe for qaar ka mid ah shirka magnetka.

Alaabooyinka la habeeyey: Magnet giraantayada waxaa laga beddeli karaa 3mm-200mm dhexroorka dibadda ah, dhexroorka gudaha 1mm-150mm, dhumucdiisuna tahay 1mm-70mm.Waxa kale oo ay u baahan tahay daahan inta badan, sida NiCuNi, Zn, Epoxy iyo wixii la mid ah.

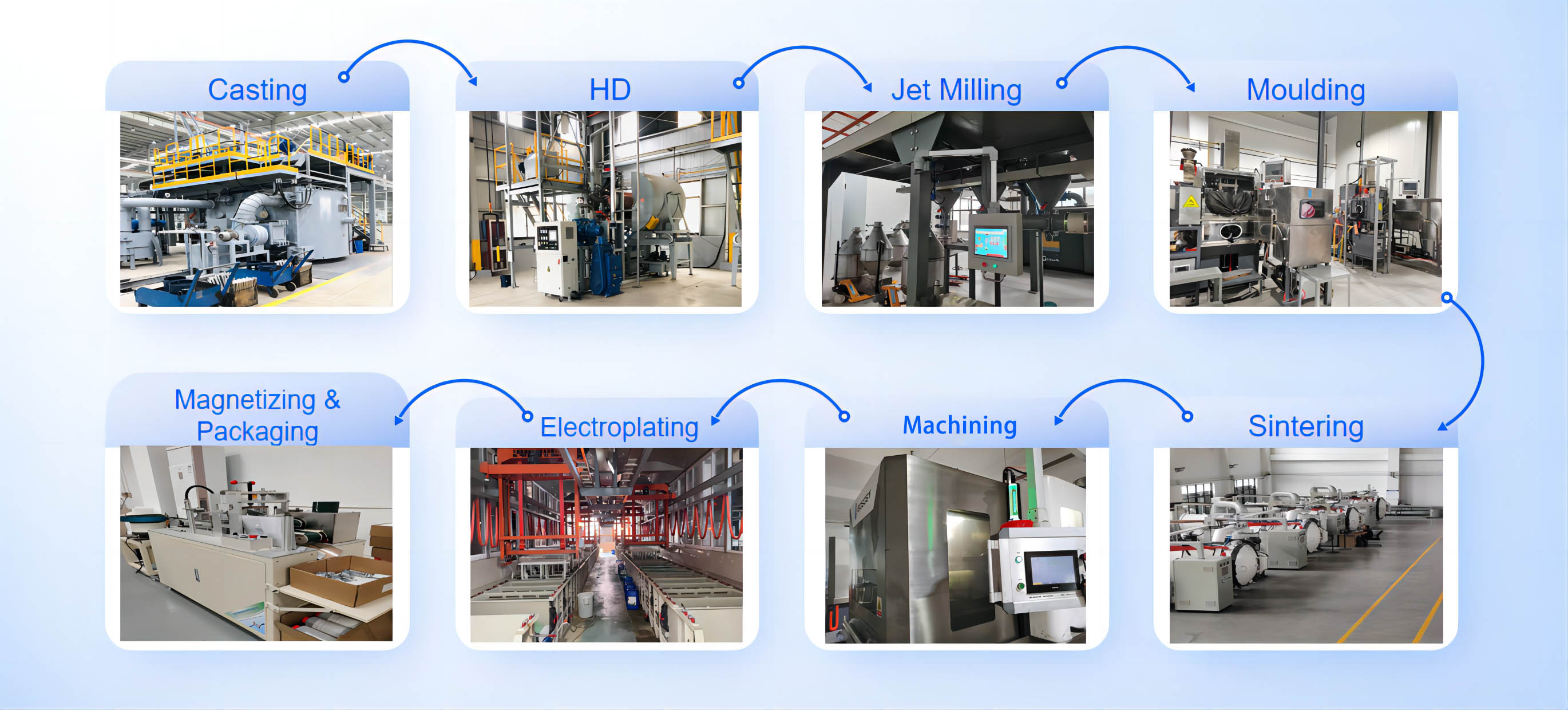

Habka Waxsoosaarka NdFeB

Hordhac Dahaarka

| Dusha sare | Dahaarka | Dhumucda μm | Midabka | Saacadaha SST | Saacadaha PCT | |

| Nikkel | Ni | 10 ilaa 20 | Silver dhalaalaya | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nickel madow | Ni+Cu+Ni | 10 ilaa 20 | Madow dhalaalaya | >48~96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5~8 | Brighe Blue Midabka dhalaalaya | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ilaa 25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 ilaa 15 | Dahab | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ilaa 15 | Silver | >12 | >48 | |

| Epoxy | Epoxy | 10 ilaa 20 | Madow/Cawlan | >48 | --- | |

| Ni+Cu+Epoxy | 15 ilaa 30 | >72~108 | --- | |||

| Zn+Epoxy | 15 ilaa 25 | >72~108 | --- | |||

| Dareenka | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah | --- | |

| Fosfate | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah) | --- | |

Astaamaha Jirka

| Shayga | Halbeegyada | Tixraaca Qiimaha | Unug |

| Kaaliyaha Magnetik Guryaha | Isku-dhafka Heerkulka La-noqon karo ee Br | -0.08--0.12 | %/℃ |

| Isku-dhafka Heerkulka La-noqon karo ee Hcj | -0.42~-0.70 | %/℃ | |

| Kuleylka Gaarka ah | 0.502 | KJ · (Kg ·℃)-1 | |

| Heerkulka Curie | 310 ~ 380 | ℃ | |

| Mechanical Physical Guryaha | Cufnaanta | 7.5-7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Iska caabinta Korontada | 1.4x10-6 | μQ ·m | |

| Xoog isku dhejisan | 1050 | MPa | |

| Xoogga Jilicsan | 80 | Mpa | |

| Xoog Laabashada | 290 | Mpa | |

| Habdhaqanka kulaylka | 6 ilaa 8.95 | W/m ·K | |

| Modulka dhalinyarada | 160 | GPA | |

| Balaadhinta kulaylka (C⊥) | -1.5 | 10-6/℃-1 | |

| Balaadhinta kulaylka (CII) | 6.5 | 10-6/℃-1 |

Muujinta Sawirka