Isu tinoshandisa no-dysprosium formula pane yakatenderedza-yakaderera-giredhi zvigadzirwa zvevatengi kuderedza mutengo.Isu tine yakagadzikana formula iyo inogona kugadzirwa kuita yakaderera tembiricha coefficient zvigadzirwa.Iyo inoderedza mutengo uye inowedzera kushanda zvakanaka kune vatengi vanonyatso kudzora kushivirira mukugadzirisa uye kupfeka zvinoenderana nezvinodiwa zvakasiyana zvevatengi kuti ive nechokwadi chekugadzikana kwekudzivirira kweplating panguva imwe chete, kusanganisira munyu wekupfapfaidza, kubatanidza simba rekuvhara, colloid affinity uye zvichingodaro. .

Zvigadzirwa zvakatenderedza zvinotarirwa nekushaikwa makona mukugadzira maitiro.Saka isu tine otomatiki yakazara yakazara yekuongorora michina yekushivirira kwechitarisiko, iyo inogona kuona kukanganisa kwechigadzirwa mukati meiyo inodzoreka renji uye kudzivirira zvigadzirwa zvakakanganisika mukushandisa maitiro.

Panyaya ye flux kuenderana, isu tinoona yakagadziriswa-poindi sintering choto kune kuenderana kwemagineti process control, uye magineti flux yakazara yekuongorora michina yekudzivirira isina simba magineti zvigadzirwa kubva mukuyerera kune vatengi.Panyaya ye magnetization kurongedza, kambani yedu ine otomatiki coding magnetization michina kudzivirira vashandi kubva pakukanganisa magineti.

Panyaya yekudzora kutakura, nhamba yakakura yeakawanda-mitsara yekucheka michina, slicing mayuniti, akakura ehunyanzvi ekugadzirisa vashandi, akakwana chigadzirwa maitiro ekutarisa, imwe neimwe nhanho yekugadzira chigadzirwa uye kugadzira inogona kuwana kufambira mberi mhinduro chero nguva, yakakura cylindrical chigadzirwa mutsara, kuve nechokwadi chekutonga kwevatengi zvinodiwa pakuunzwa kwechigadzirwa, pamwe neinodzoreka kugadzirwa kufambira mberi.

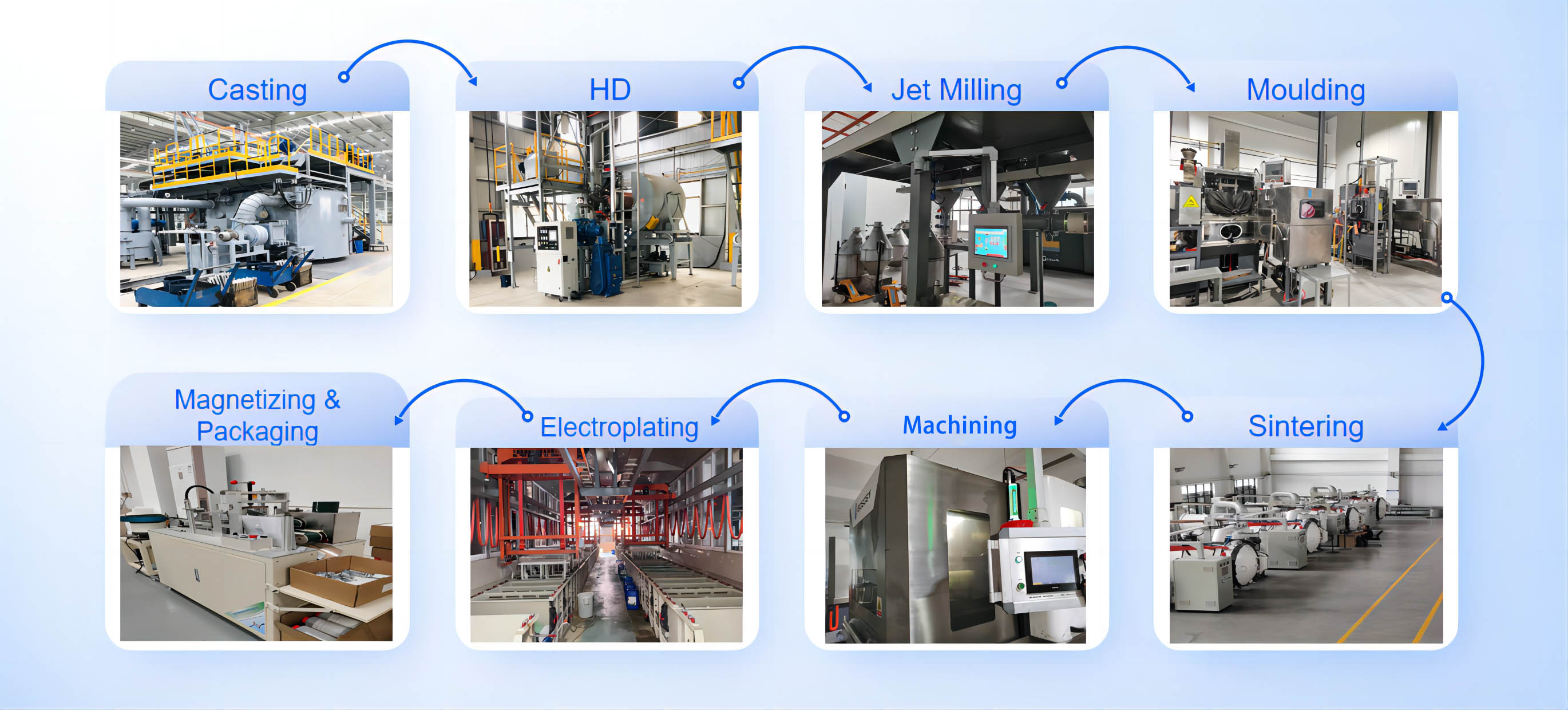

NdFeB Kugadzira Maitiro

Coating Nhanganyaya

| Surface | Coating | Ukobvu μm | Color | Maawa eSST | PCT Maawa | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5~8 | Brighe Blue Shining Color | >16 -48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Sirivha | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Ndarama | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Sirivha | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Dema/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Gray | Kudzivirira Kwenguva | --- | |

| Phosphate | --- | 1~3 | Dark Gray | Kudzivirirwa Kwenguva pfupi) | --- | |

Hunhu Hwenyama

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties | Reversible Temperature Coefficient yeBr | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties | Density | 7.5~7.80 | g/cm3 |

| Vickers Kuoma | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Simba | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Kuwedzera Kwekupisa(C⊥) | -1.5 | 10-6/℃-1 | |

| Kuwedzera kweThermal (CII) | 6.5 | 10-6/℃-1 |

Mufananidzo Kuratidzwa