Utimur sine dysprosio formulae productorum rotundorum low-gradarum pro clientibus ad gratuita reducenda.Habemus formulam stabilem quae in productos coëfficientes humilis temperatus fieri potest.Sumptus reducit et efficaciam auget amplius pro clientibus cum stricte moderatur tolerantia in dispensando et litura secundum varias clientium exigentias ut stabilitatem platonis tutelae simul, incluso salis imbre, efficiens vim obligandi, affinitatem colloidorum, et sic porro. .

Circum producta prona sunt ad angulos absentis in processu productionis.Lorem ipsum habemus apparatum plenum inspectionis ad apparentias tolerantias, quae efficere possunt defectus productos intra ambitum moderandi et defectus fructus vitare in processu utendo.

Secundum fluxum constantiae, fornacem sintering fixam curamus ad constantiam processus magnetis refrenandam, et fluxum magneticum plenam inspectionem instrumentorum ne debilium magneticam res fluit ad clientes.Secundum compages magneticae, societas nostra instrumenti magneticae automatic coding indagare, ne curatores criminis magnetici obeundo sint.

Secundum traditionis imperium, magnus numerus machinarum multi-linearum secantium, unitas dividentium, operariorum processus technici perfecti, processus producti perfecti vigilantia, quilibet gradus processui et productionis progressus aliquando potest accipere, cylindricum producere lineam productam maturam; ut mos imperium requisita ad productionem partus, necnon progressionem productionis moderatior.

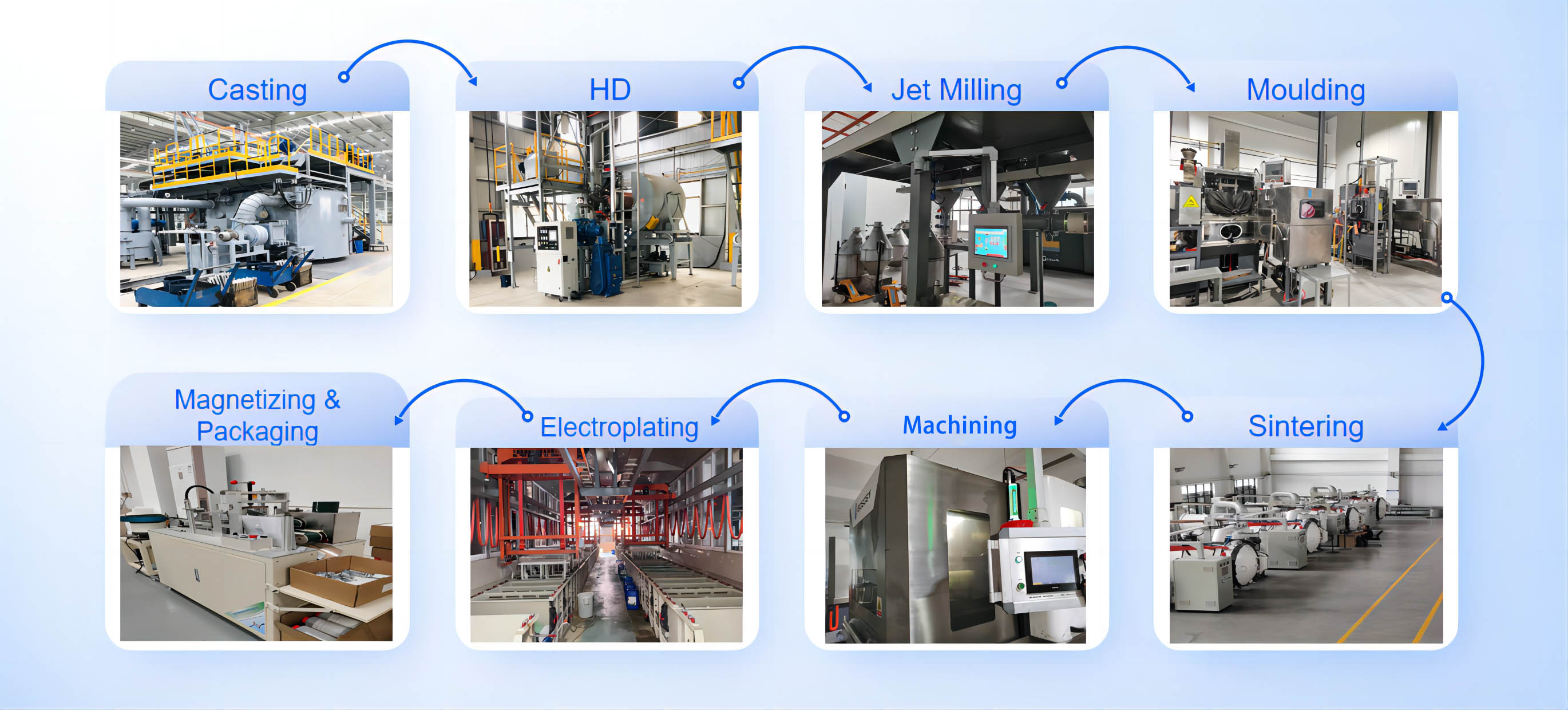

NdFeB Processus Productio

Introductio coating

| Superficies | Coating | Crassitudo μm | Color | SST Horae | PCT Horae | |

| Nickel | Ni | 10~20 | Clara Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nigrum Nickel | Ni+Cu+Ni | 10~20 | Clara Niger | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5~8 | Bright Blue Lucens Color | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Argenti | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Aurum | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Argenti | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Nigrum / Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| passionem | --- | 1~3 | Griseo | Tempus Praesidium | --- | |

| Phosphate | --- | 1~3 | Griseo | Tempus Praesidium) | --- | |

Characteres corporei

| Item | Morbi laoreet | Reference Precium | Unitas |

| Auxiliaris Magnetic Properties | Reversible Temperature Coefficiens Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficiens Of Hcj | -0.42~-0.70 | %/℃ | |

| Imprimis Caloris | 0.104 | KJ·(Kg·℃)-1 | |

| Curie Temperature | 310~ 380 | ℃ | |

| Mechanica Physica Properties | Density | 7.5~7.80 | g/cm*3 |

| Vickers duritia | 650 | Hv | |

| Electrical Resistentia | 1.4x10-6 | μQ ·m | |

| Compressive fortitudo | 1050 | MPa | |

| Distrahentes fortitudo | 80 | Mpa | |

| inflexio Fortitudo | 290 | Mpa | |

| Scelerisque conductivity | 6~8.95 | W/m ·K | |

| Modulus | 160 | GPa | |

| Scelerisque Expansion (C⊥) | -1.5 | 10-6/℃-1 | |

| Scelerisque Expansion (CII) | 6.5 | 10-6/℃-1 |

Picture Display