Daim ntawv thov: NdFeB nplhaib yog dav siv nyob rau hauv hollow khob lub cev muaj zog, lub tshuab nqus tsev vacuum lub cev muaj zog, plaub hau tshuab lub cev muaj zog, hais lus nrov thiab lwm yam teb.Hauv kev siv lub cev muaj zog, nws muaj qhov xav tau ntawm cov hlau nplaum geometric qhov ntev thiab cov khoom siv hlau nplaum, qhov tsawg kawg nkaus kam rau ua nyob rau hauv 0-0.03mm.Hauv daim ntawv thov nrov nrov, cov hlau nplaum feem ntau nrog Zn txheej, xa nyob rau hauv un-magnetized mob, qib hlau nplaum zoo li N, M thiab H series qib, ib txwm nrov nrov hlau nplaum tsis xav tau qib siab dua.Lwm daim ntawv thov yog rau kev ua lag luam kom zoo nkauj, peb muab ntau lab daim nplhaib hlau nplaum rau peb cov neeg siv khoom thoob plaws ntiaj teb, cov hlau nplaum yog siv rau lub thawv ntim khoom, axial magnetized. los yog multipole axial magnetized zoo li 2 lossis 4 ncej, thiab tsis yog rau cov hlau nplaum ntshiab xwb, peb kuj yog avaialbe rau qee cov hlau nplaum sib dhos.

Cov khoom lag luam customized: Peb lub nplhaib hlau nplaum tuaj yeem hloov kho los ntawm 3mm-200mm txheej txoj kab uas hla, 1mm-150mm puab txoj kab uas hla, tuab ntawm 1mm-70mm.

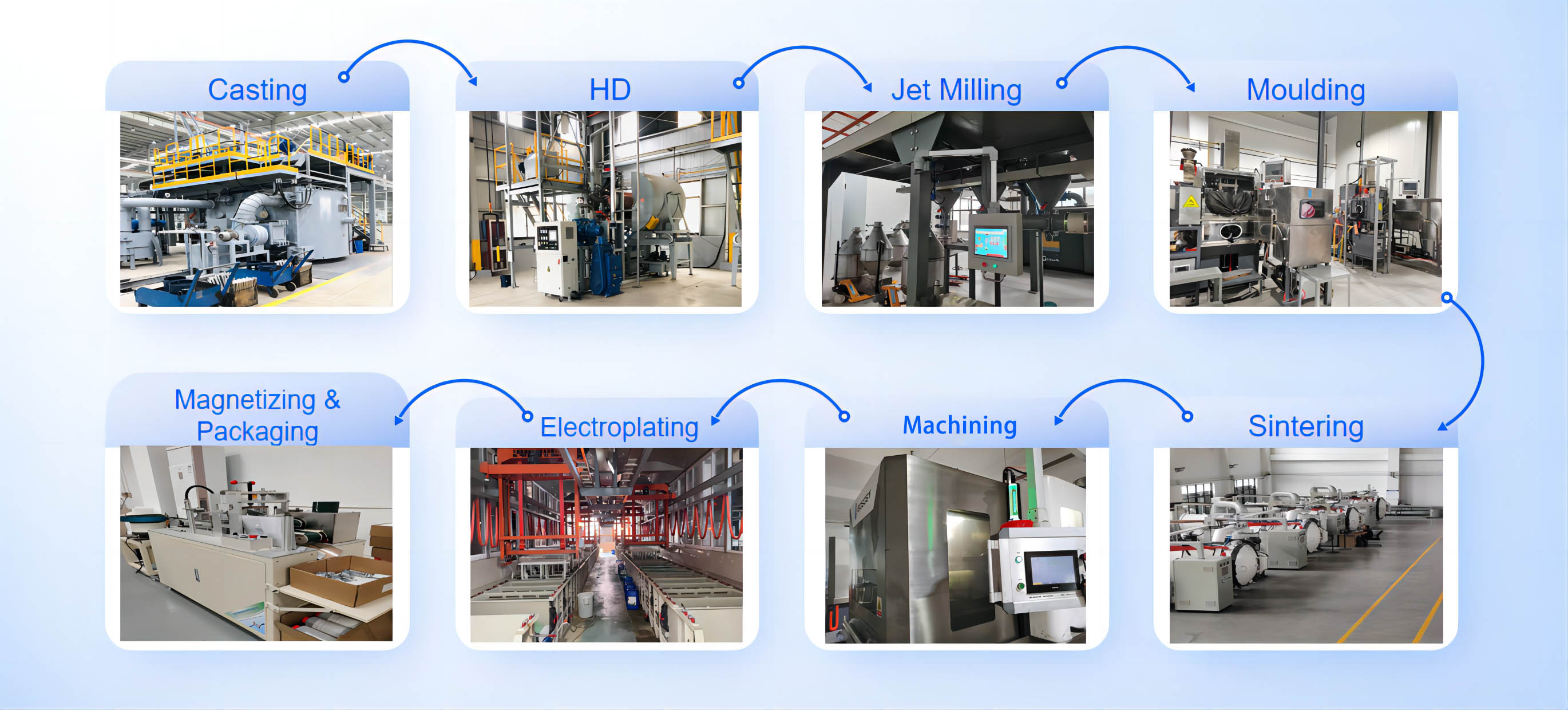

NdFeB Production Process

Txheej Taw Qhia

| Nto | Txheej | Thickness μm | Xim | SST Sijhawm | PCT Sijhawm | |

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| Dub Nickel | Ni+Cu+Ni | 10 ~ 20 | Xim dub | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5 x8 | Brighe Blue Xim Xim | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Nyiaj | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Kub | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Nyiaj | > 12 | > 48 | |

| Epoxy | Epoxy | 10 ~ 20 | Dub / Grey | > 48 | --- | |

| Ni + Cu + Epoxy | 15-30 Nws | > 72–108 | --- | |||

| Zn + Epoxy | 15 ~ 25 | > 72–108 | --- | |||

| Passivation | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus | --- | |

| Phosphate | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus) | --- | |

Cov yam ntxwv ntawm lub cev

| Yam khoom | Tsis muaj | Siv tus nqi | Chav tsev |

| Sib Nqus Sib Nqus Cov khoom | Reversible Temperature Coefficient Ntawm Br | -0.08 - 0.12 | % / ℃ |

| Reversible Temperature Coefficient Ntawm Hcj | -0.42~-0.70 | % / ℃ | |

| Tshwj xeeb kub | 0.502 ib | KJ·(Kg· ℃)-1 | |

| Curie Kub | 310-380 : kuv | ℃ | |

| Mechanical Physical Cov khoom | Qhov ntom | 7.5-7.80 Nws | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Hluav taws xob Resistance | 1.4x10-6 | μQ os | |

| Compressive zog | 1050 | MPa | |

| Tensile zog | 80 | Mpa | |

| Khoov zog | 290 | Mpa | |

| Thermal conductivity | 6: 8,95 | W/m · K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion (C⊥) | -1.5 | 10-6 ℃ -1 | |

| Thermal Expansion (CII) | 6.5 | 10-6 ℃ -1 |

Daim duab Display