Muna amfani da dabarar no-dysprosium akan samfurori masu ƙarancin ƙima don abokan ciniki don rage farashi.Muna da tsayayyen tsari wanda za'a iya sanya shi cikin samfuran ƙarancin zafin jiki.Yana rage farashin kuma yana ƙara haɓaka haɓaka ga abokan ciniki tare da tsananin sarrafa juriya a cikin aiki da sutura bisa ga buƙatun abokan ciniki daban-daban don tabbatar da kwanciyar hankali na kariyar plating a lokaci guda, gami da fesa gishiri, dauri mai ƙarfi, alaƙar colloid da sauransu. .

Samfuran zagaye suna da haɗari ga kusurwoyi masu ɓacewa a cikin tsarin samarwa.Don haka muna da cikakken kayan aikin dubawa ta atomatik don jurewar bayyanar, wanda zai iya tabbatar da lahani na samfur a cikin kewayon sarrafawa kuma ya guje wa samfurori mara kyau a cikin amfani da tsari.

Dangane da daidaiton juzu'i, muna tabbatar da ƙayyadaddun madaidaicin madaidaicin wutar lantarki zuwa daidaiton sarrafa tsarin maganadisu, da magnetic flux cikakken kayan aikin dubawa don hana samfuran magnetic rauni daga kwarara zuwa abokan ciniki.Dangane da marufi na maganadisu, kamfaninmu yana da waƙa ta atomatik kayan aikin maganadisu don hana ma'aikata yin cajin cajin maganadisu.

A cikin sharuddan bayarwa iko, babban adadin Multi-line yankan inji, slicing raka'a, balagagge fasaha aiki ma'aikata, cikakken samfurin tsari saka idanu, kowane mataki na samfurin aiki da kuma samar iya samun ci gaba feedback a kowane lokaci, balagagge cylindrical samfurin samar line, don tabbatar da buƙatun kulawar abokin ciniki don isar da samfur, da kuma ci gaban samar da sarrafawa.

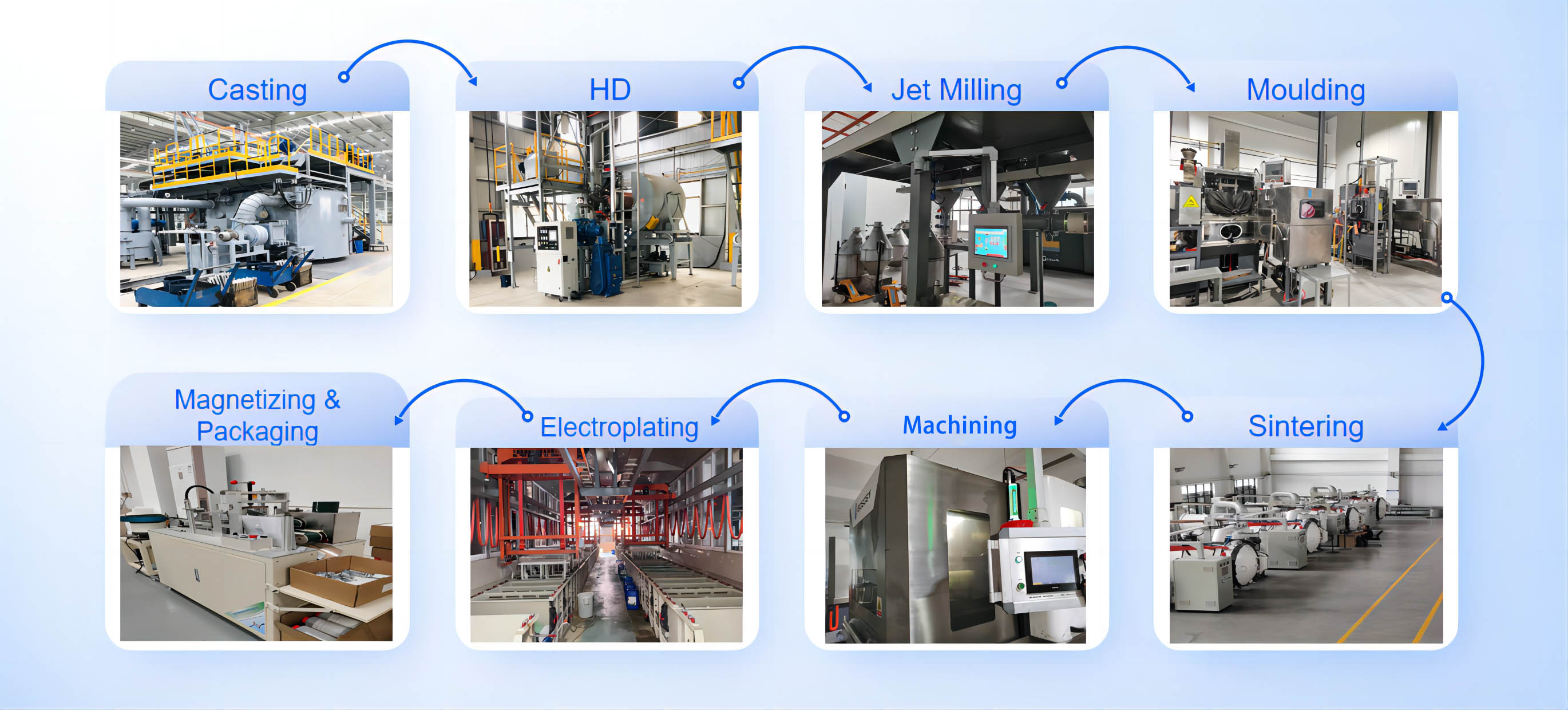

Tsarin Samar da NdFeB

Gabatarwa mai rufi

| Surface | Tufafi | Kauri μm | Launi | Sa'o'i SST | Awanni PCT | |

| Nickel | Ni | 10 zuwa 20 | Azurfa mai haske | >24;72 | >24;72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10 zuwa 20 | Baƙar fata mai haske | >48;96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5 zuwa 8 | Brighe Blue Launi mai sheki | > 16 zuwa 48 > 36 ~ 72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 zuwa 25 | Azurfa | > 36 ~ 72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 zuwa 15 | Zinariya | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 zuwa 15 | Azurfa | >12 | >48 | |

| Epoxy | Epoxy | 10 zuwa 20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15 zuwa 30 | > 72 ~ 108 | --- | |||

| Zn+Epoxy | 15 zuwa 25 | > 72 ~ 108 | --- | |||

| Abin sha'awa | --- | 1 ~3 | Dark Grey | Kariya na wucin gadi | --- | |

| Phosphate | --- | 1 ~3 | Dark Grey | Kariya na wucin gadi) | --- | |

Halayen Jiki

| Abu | Ma'auni | Ƙimar Magana | Naúrar |

| Magnetic Auxiliary Kayayyaki | Matsakaicin Yanayin Zazzabi Na Br | -0.08-0.12 | %/ ℃ |

| Matsakaicin Yanayin Zazzabi Na Hcj | -0.42-0.70 | %/ ℃ | |

| Takamaiman Zafi | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Zazzabi | 310-380 | ℃ | |

| Injiniyan Jiki Kayayyaki | Yawan yawa | 7.5 ~ 7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Juriya na Lantarki | 1.4x10-6 | μQ · m | |

| Ƙarfin Ƙarfi | 1050 | MPa | |

| Ƙarfin Ƙarfi | 80 | Mpa | |

| Karfin Lankwasa | 290 | Mpa | |

| Thermal Conductivity | 6 zuwa 8.95 | W/m · K | |

| Modul na Matasa | 160 | GPA | |

| Thermal Fadada (C⊥) | -1.5 | 10-6 / ℃-1 | |

| Fadada thermal (CII) | 6.5 | 10-6 / ℃-1 |

Nunin Hoto